|

| Longest Distance Darts Bullseye World Record Attempt (youtube video) |

If you're looking to break the record for the longest distance bullseye on a dartboard how do you do it? You throw lots of darts.

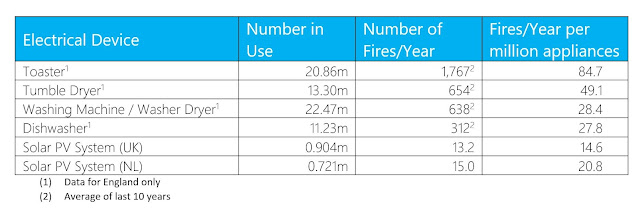

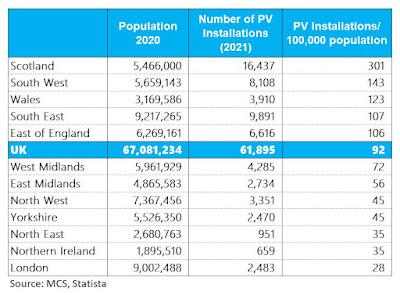

Solar is a very safe technology. It's less dangerous than a toaster or a tumble dryer (see my earlier blog putting solar risks into context). But just like when trying to hit the bullseye, the more solar that is installed, the greater is the chance that low-probability, high-consequence events like solar fires occur.

But fires have already been happening and, as the examples below show, they occur in all types of installation - rack-mounted above pitched roofs, flat roof installations and roof integrated BIPV, and unlike a toaster, solar PV is often spread over and through the building, so the outcome of a solar fire can be very significant.

|

Rack mounted above roof solar, 2017, Bow Wharf, Bethnal Green, London

|

|

Flat roof solar, 2016, Denekamp, Utrecht, Netherlands

|

|

| Roof integrated solar, 2018, Vinkeveen, Netherlands |

Insurance companies are becoming more and more aware of the risks of solar fires and if the solar industry wants to avoid having impractical or poorly thought through 'solutions' imposed upon it, then we need to collectively do more to improve the safety of the solar systems we design and install.

Back in the early 1960s many people wouldn't have thought twice about jumping into a car with a few glasses of beer on board - a legal drink drive limit didn't come into force in the UK until 1967. Nor would they worry about speeding off without the benefits of driver, passenger and side air bags, side impact protection bars, or an anti lock braking system to keep them safe. Although the car would probably be equipped with a 3-point seatbelt (they were invented in 1959) there was no legal requirement to use it and many people didn't.

Safety is constantly improving. Risks people were once happy to accept now seem unthinkable in from the vantage point of today.

In this blog we're going to take a look at two recent research studies that have advanced understanding of the causes of solar PV fires and try to answer the questions "what components are most likely to be the source of fire, and what can be done to improve the fire safety of solar installations?"

Solar Fire Research

BRE Solar Fire Study

Researchers from the Building Research Establishment (BRE) investigated 80 fires in the UK that involved solar PV systems in some way, either because it was a potential source of the fire or because it was involved in a fire that started elsewhere. (Link to report here).

The solar PV system was found to be the source of the fire in 56 of the incidents. Of these 22 were serious fires (that were difficult to extinguish and spread beyond the point of origination), with the remainder being classified as localized or ‘thermal events’ (smoking, overheating).

- Between 26 and 28 of these were linked to the DC isolator (43% of fires)

- Between 6 and 11 to the DC cables and connectors (17% of fires)

- 6-9 at the inverter (14% of fires) and

- 2-5 in the module.

No information is given in the report on which causes of fire were more likely to result in serious fires. Correspondence with one of the authors of the report on this question clarified that it wasn't recorded and that the numbers were likely to be too small to draw a conclusion in any case.

TNO Solar Fire Study

This report by Dutch researchers at TNO was written in response to a number of solar fires in the Netherlands during 2018 that made the news in local media. Unlike the UK research which visited sites and collected physical evidence, the TNO project was limited to compiling a register of incidents and interviewing residents, damage experts, fire service staff and solar installers. The available budget did not reach to in-depth analysis or forensic examination of fires. (Link to report here).

According to the TNO study of solar fires in Netherlands, more than 80% of incidents investigated started with the DC connectors.

Differences in Conclusions

So why the differences between UK and Netherlands studies?

The first thing to note is that using a separate DC isolator has been the most prevalent approach in the UK, whereas in the Netherlands installers have instead preferred to use an inverter with an integrated DC isolation switch, removing a component from the system that installers in the UK were clearly struggling to install safely.

It is also worth noting that the Netherlands study was based primarily on interviews with insurance industry loss adjusters, and that incidents were identified by a search of media articles, whereas the UK study engaged with the Fire Service over the course of the project and so included incidents that had not developed into serious fires.

The bias towards connectors as the source of Dutch fires suggests that connector failures might be more likely to result in a serious fire leading to an insurance claim. If they are lower probability than other types of failure, this suggests that a connector failure is more likely to become of high consequence.

How to Reduce Fire Risks in Solar Systems

The risk assessment framework is helpful to think about what steps can be taken to reduce risks of fire in PV systems.

If we’ve identified a hazard of a break in the circuit leading to an electrical arc leading to a fire, we should think about what might cause it, and what precautions we might take to prevent it. The controls we apply should follow the hierarchy of hazard controls - starting with elimination of the risk - for example by redesigning the system to remove or reduce the number of potential failure points, or engineering controls that help prevent the arc conditions forming in the first place, or that prevent the development of an arc into a fire. (Read my blog about electric arcs and solar PV here)

DC Isolator

Not mentioned in the TNO report, the DC isolator is by some margin the number one source of solar fires in the BRE report. The causes identified in the BRE report were installation practices and product selection. Typical errors included using a cheaper AC isolator instead of a specialised DC isolator, cable entry from above or running more than one cable through an entry gland - both allowing water into the DC isolator causing corrosion and leading to arcing.

Fortunately the price premium for DC isolators has gone down, reducing the incentive for installers to replace it with an AC isolator. The Microgeneration Certification Scheme has also done a good job of incorporating learnings from the BRE report into the UK solar installation standards.

The most effective control is to remove a hazard completely, and since inverters are now available with the DC isolator built in, the UK industry should follow the example of installers in Netherlands by specifying inverters with DC isolation switches as standard.

DC Cabling

DC Cabling > Failure Mode > Damage > Rodent Damage

Rodents like to chew cables, with the risk that a damaged cable would have a narrow gap across which an electric arc may strike, starting a fire.

The most obvious mitigation against this risk is to exclude rodents from the area where cables are running. For above-roof systems this might be achieved with a wire mesh fitted around the perimeter of the solar panel, as is common for excluding nesting birds, though a finer mesh may be needed. For roof integrated systems it is possible to choose a system without gaps between the solar panel and the roof covering.

DC Connectors

DC Connector > Failure Mode > Incomplete Insertion

PV solar panels are supplied with push-fit connectors on the end of flying leads. When pushed fully together, these form a waterproof (IP65, IP68) connection that cannot be pulled apart due to snap-in locking tabs. So, a first failure mode for connectors is to push them together far enough to make an electrical connection, but not far enough to lock them together on the locking tab. Any tension on the DC cable could then cause the connector to withdraw and create a gap which could lead to arcing within the connector.

Installer competency - listening for the click from the locking mechanism and giving a pull to check engagement will mitigate against the risk or poorly assembled connectors.

|

| Smaller format solar = more connections = more risk |

Again, looking to remove the hazard by eliminating the component, we reduce the chance of this happening if we reduce the number of connections that need to be made. Solar panels have been growing in size, and the more watts-peak (Wp) per panel, the lower the number of connectors that are present in a solar installation. Solar tiles or slates have a far greater number of connections per kWp due to their small format, so increasing the number of DC connectors in a system.

DC Connector > Failure Mode > Cross-mated Connectors

|

| Cross mated MC4 and "MC4 compatible" connectors |

Another failure mode is connection faults arising from the cross-mating of dissimilar DC connectors from different manufacturers. This is forbidden in principle in both the UK (by MIS3002) and Netherlands (by NEN1010), but in practice it is difficult to comply with, and almost impossible to police - read my earlier blog on the fire risks from cross-mating DC connectors.

Since 2019 Viridian Solar has only fitted genuine Staubli MC4 connectors to its Clearline fusion solar panels, guaranteeing compatibility and enabling installers to easily purchase matching connectors locally for extension cables. While the solar industry awaits the development of a global standard for DC solar connectors that would ensure inter-operability of different plugs and sockets, I would urge that panel manufacturers at the very least should declare the manufacturer of the DC connector on the solar panel nameplate to allow installers to comply with local regulations the prohibit the mixing of connectors from different manufacturers.

DC Connector > Failure Mode > Poor Crimped Joint Quality

A third failure mode occurs where cables need to be added to the circuit to bridge longer distances, such as between panel rows or from the panels to the inverter. The solar installer needs to make a crimp joint on site to join a DC connector to a cable of the right length.

Tests published by Staubli shows the importance of correct crimping. It is possible to make a crimp with a set of pliers instead of using the proper tools, which could easily happen given the cost differential and convenience of using pliers instead. However, the pull-out resistance and resistance to corrosion are both severely compromised. Either could lead to arcing in the connector, in turn leading to a fire.

Again, installer training and competence is the best way to avoid this risk.

DC Connector > Risk Mitigation > Enclosure

|

| DC Connector Enclosure Device |

If you can't eliminate or substitute a component, the next step in the risk reduction hierarchy is to apply a control to isolate the hazard. An example of this approach is the new ArcBox solar connector enclosure. A clamshell containment device that snaps around the DC connector and, should an electric arc form inside a DC connector, stops it spreading to combustible material around the connector and preventing the failure developing into a fire.

General > Risk Mitigation > Arc Fault Circuit Interrupter (AFCI)

|

| Huawei inverter with AFCI |

Inverter manufacturers are now offering

Arc Fault Circuit Interruption (AFCI) as a product feature. This approach continuously monitors the frequency of electrical noise on the DC current or voltage signal, disconnecting the circuit within 2.5 seconds (IEC 63027) whenever noise that is characteristic of an arc is detected. The system resets after a period, with the period before reset increasing each time an arc is detected until a manual reset is required if the device resets more than 5 times in 24 hours.

One challenge with this approach is that electrical noise from naturally occurring sources may be difficult to distinguish from an arc - which may cause nuisance tripping.

General > Risk Mitigation > Eliminating Combustible Materials

Another control measure to reduce the risk an electrical arc fault develops into a serious fire is to ensure that combustible material is not installed or allowed to accumulate around the solar panels.

Birds and small mammals find the space behind a solar panel an attractive place to build nests. Wind-blown debris can also accumulate behind some solar panel systems. Some manufacturers recognize the risk and instructions require users to go on the roof and clean it out. Better to specify a solar system that does not have openings that allow animals, birds or wind blown ‘foreign materials’ access to the area behind the panel.

Some in-roof solar mounting systems are comprised of sheets or trays of plastic cladding placed behind the solar panels to provide a waterproofing layer. This obviously adds to the 'fuel' available to any fire that might start, and a risk mitigation measure would be to avoid mounting systems that add combustible materials to the installation in this way.

In Conclusion

Solar is a safe technology, but there are many ways to make it even safer - and this will become more and more necessary as the number of solar installations increases in coming years.

Some of these risk mitigation opportunities add cost to the installation, others are costless and require only more diligence in installation or simple specification choices that can reduce the risk of a fault condition progressing to become a full-blown fire. It is likely that both and all forms of risk reduction will be necessary to meet the demands of customers and insurers. If the industry doesn't act of its own accord, it may have change forced upon it.

McTaggartGroup-ViridianSolar.jpg)

ViridianSolar.jpg)