What is the fuss about PERC?

Anyone who follows the latest developments in the Solar Photovoltaic market will have come across the technical term PERC at least once in the past year or so. All respectable suppliers compete to launch the best PERC as a means to secure the premium part of the market share.

PERC stands for Passivated Emitter Rear Cell; the concept was first proposed by the University of New South Wales in a grant report in 1984 (1). As a matter of fact, the modern PERC generally refers to two specific configurations called PERT (Passivated Emitter, Rear Totally-diffused), and PERL (Passivated Emitter, Rear Locally-doped), which have proven to be the most viable solutions amongst other PERC configurations (2).

The PERC concept has taken some time to meet with commercial success, with the first high efficiency solar cells being fabricated in a lab with up to 20% efficiency from the 1990s onwards (3). Obviously at the time, there were other competing technologies, e.g. back contact and HIT. Hence, the PERC concept was only one of many promising ideas to increase solar cell efficiency. It took nearly 30 years for the industry to catch up with the concept and produce efficiencies achieved at the research level.

How does a PERC Solar Cell work?

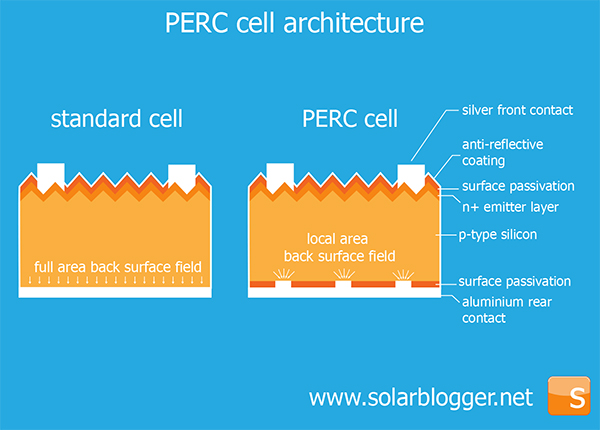

In a nutshell, a PERC solar cell can be created by adding a rear surface passivation film to a conventional crystalline cell. In practice, it involves two additional steps: first, a rear passivation film is applied. Then, either lasers or chemicals are used to open up tiny pockets in the film through which the rear conducting layer can contact the silicon below the passivation layer. Figure 1 compares the configurations of conventional and PERC solar cells.

|

| Figure 1: Comparison of cell configurations |

1. By minimising surface recombination

The atoms at the surface of a silicon wafer have 'dangling bonds' which can capture charge carrying electrons and pull them back into the silicon crystal structure (a process called surface recombination). As a result, when an electron reaches the back surface of a conventional solar cell, it is likely to be captured and does not contribute to the current. However in a PERC solar cell, a passivated film is grown on the back surface of the solar cell and reduces this effect by tying up the 'dangling bonds'. A charge carrying electron that strays too close to the back surface is allowed to continue on its way and the chance it will reach the emitter and contribute to the electric current produced by the solar cell is increased. (Figure 2).

|

| Figure 2 - How a PERC cell increases efficiency by decreasing surface recombination. |

Longer wavelengths (red light) generate electrons near the back surface, compared to shorter wavelengths (blue light) (4). Since the PERC solar cell helps prevent surface recombination, it will still be able to capture these wavelengths (5). This capability increases the solar cell performance during mornings and evenings when longer wavelengths are present, which leads to the claims of better weak light performance by many manufacturers.

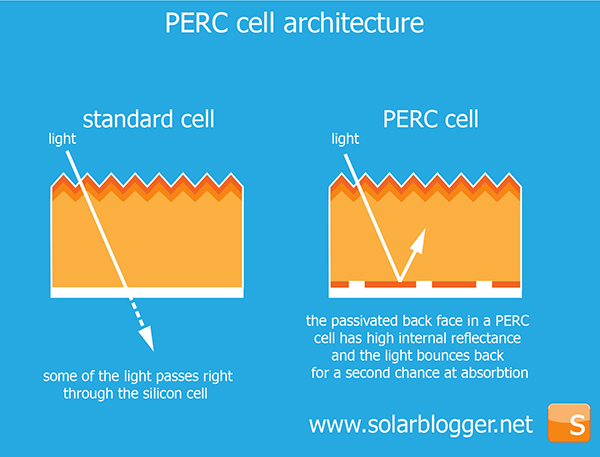

2. By Increasing Internal Reflectivity to Capture More Light

The rear film reflects the light that passes through the solar cell without being absorbed. This provides the light with more opportunity for a second absorption attempt (see Figure 3). In other words, the efficiency of energy conversion is just becoming higher.

|

| Figure 3 PERC cell increases efficiency by reflecting light back through the solar cell |

3. By Reflecting Counter-productive Wavelengths

Generally, silicon solar cells stop absorbing wavelengths above 1180 nm, instead they are absorbed by the backside metallisation layer and tuned into heat (4). The rear passivated film reflects these counter-productive wavelengths out of the solar cell and hence maintains cooler temperatures. As a result, PERC solar cells are considered to have better heat resistance.

All of the above, if manufactured correctly, will undoubtedly increase the solar cell efficiency. The current commercially available PERC solar cells are in excess of 20% with a record efficiency of nearly 23%. As this technology is piggybacked on conventional silicon solar cells, you can bet the efficiency will not stop here and will keep on improving!

Why has it become the most exciting feature amongst the new PV technologies?

It has been a holy grail in the PV industry to find a product with the highest possible efficiency, while maintaining the low manufacturing cost. To some extent, PERC solar cells provide the answer. Hence, it is not surprising that this technology has a rosy outlook.

From standstill, the PERC commercial production capacity is expected to occupy nearly half of the total solar PV cell capacity by 2020 (see Figure 4) (6).

|

| Figure 4: Global production capacity for PV cells from 2016 to 2020 (Source: Energy Trend) |

The main attraction is that the PERC production requires minimum modifications to existing solar cell manufacturing lines. The existing lines can easily be upgraded to produce PERC solar cells without having to invest in large capital expenditures or completely overhaul the entire lines.

In other words, one could increase the solar cell efficiency without having to take huge financial risks. Meanwhile, by recycling most of the existing equipment, one simply makes the money work harder for the original investment. It appears to be a no brainer.

Too good to be true?

Despite the PERC being a thirty year old concept, they have not been tested commercially until quite recently. It was first reported by Ramspeck (7) that PERC cells can exhibit stronger power degradations during the early days through a process called light-induced degradation (LID).Fraunhofer Centre for Silicon Photovoltaics in Germany subsequently conducted extensive research to find out the degradation mechanism due to illumination (8). They were mainly attributed to chemical and physical root causes, namely Boron-oxygen complex activation and Iron-boron pair dissociation for the former, and elevated temperature for the latter.

To be fair, LID is not a new phenomenon, affecting conventional solar cells too. This type of degradation has simply entered the spotlight with the introduction of mass-produced PERC solar cells.

In response, some cell manufacturers have addressed the issue by adopting small changes to the solar cell process, such as modified process temperatures and different wafer materials (9).

Conclusions

PERC is going to take centre stage in the foreseeable future. This technology will progressively take a bigger market share – the benefits to developers, designers and installers are obvious.

Sooner or later, most of the PV modules will feature this technology. One just has to carefully choose trusted, quality suppliers with proven test records.

This fuss is, after all, worth paying attention to.

References

1. M.A. Green, A.W. Blakers, J. Kurianski, S. Narayanan, J. Shi, T. Szpitalak, M. Taouk, S.R. Wenham and M.R. Willison, Ultimate Performance Silicon Solar Cells, Final Report, NERDDP Project 81/1264, Jan. 82-Dec. 83 (dated Feb., 1984).

2. M.A. Green, The Passivated Emitter and Rear Cell (PERC): From conception to mass production, Solar Energy Materials & Solar Cells, 143 (2015) 190-197.

3. C.J. Chiangand, E.H. Richards, A 20% efficient photovoltaic concentrator module, conferencerecord,21st IEEE Photovoltaic Specialists Conference, Kissimmee, May 1990, pp.861–863.

4. D. de Rooij, PPERC solar cell technology: why will PERC dominate silicon cell technology? 2015 (http://sinovoltaics.com/solar-cells/perc-solar-cell-technology-will-perc-dominate-silicon-cell-technology/).

5. PERC cells: production costs down, efficiency up. May 2016. (https://www.pv-magazine.com/press-releases/perc-cells-production-costs-down-efficiency-up_100024647/)

6. TrendForce Reports PERC Cell’s Global Production Capacity to Reach 25GW in 2017, Resulting in Doubling of Total Annual Output. 19/1/2017 (http://press.trendforce.com/press/20170119-2737.html)

7. Ramspeck, K. et al. 2012, “Light induced degradation of rear passivated mc-Si cells”, Proc. 27th EU PVSEC, Frankfurt, Germany, pp. 861–865.

8. Tabea Luka, Christian Hagendorf & Marko Turek, Multicrystalline PERC solar cells: Is light-induced degradation challenging the efficiency gain of rear passivation? Photovoltaics International, 2016

9. Haase, J. Mono as well as multi PERC cells will get a significant market share, PV Magazine 10/2015, pp.74 -77.